Drive Wire Roll Of Paper Machine

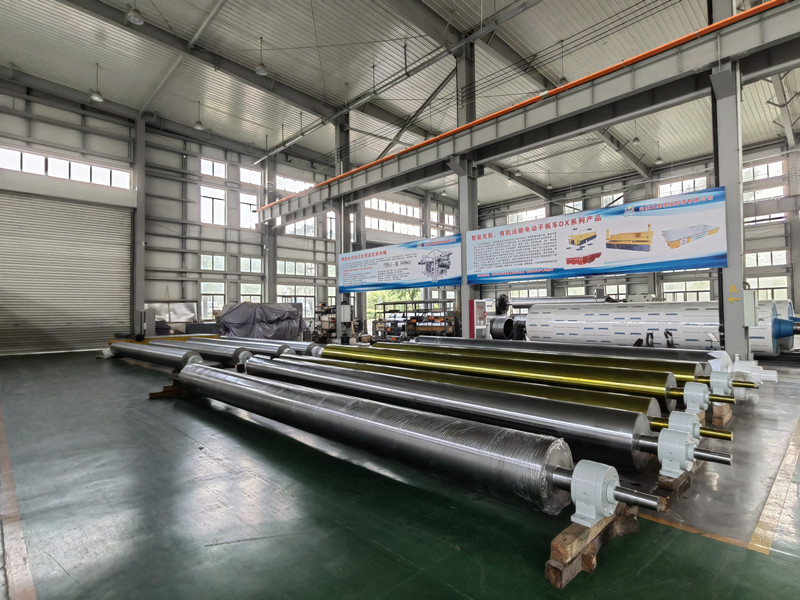

Drive wire roll of paper machine

A tube rolls with good performance is crucial for the operation of a paper machine.

High reliability and easy maintenance in the event of accidents are also important requirements for these rolls.

To meet these special needs, high-precision tube rollers with optional quick replacement heads have been developed.

Dynamic Balance In Accordance With ISO1940 Standards

Quality Grades G1.0, G1.6 and G2.5.

Drive wire roll of paper machine

Driving wire rolls | Manufacturing Standard Shell in seamless steel pipe or rolled and welded steel plate Bulkhead in HT250 or QT500-7 Journal in 42Crmo or Forged 42Crmo |

Optional Grease or thin oil lubrication Rubber cover or Chromed plating | |

Supply limits Max Diameter: 1000mm Max Face length: 14000mm Max Balancing speed: 2500m/min With Center dynamic deflection testing |

Daxing has more than 70 sets of large-scale processing and testing equipment, 11 sets of processing equipment that can process roller surface 12 meters, and the maximum processing length can reach 16 meters. Excellent equipment ensures excellent product quality, and advanced testing equipment and management concept ensure that each set of roller shaft can meet international standards.

Packaging:

1.The normal package is wooden box(Size: L*W*H). If export to european

countries,the wooden box will be fumigated.If container is too tighter,we will use film for packing or pack it according to customers special request.

2.Different products will packaged according to their shapes, weight, transport distance and transport modes. large machines will be packaged in sections. every part of export machinery will be in standard export package-seaworthy wooden case, waterproof film, straw rope, carton box etc., which will ensure the intactness of products.

ShippingSea transportation is from Qingdao seaports or other china main ports. The delivery time is decided by machine types.But we also try to make it follows your needs.