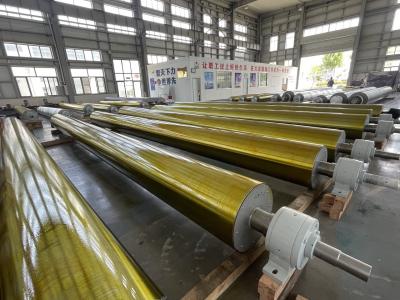

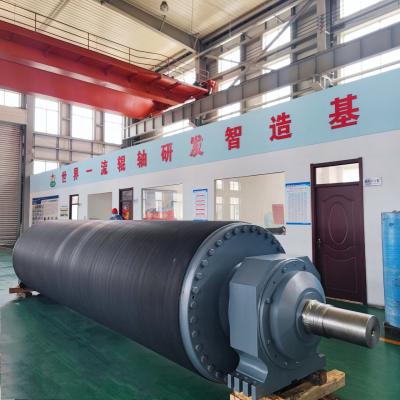

Wire Guide Roll

A tube rolls with good performance is crucial for the operation of a paper machine.

High reliability and easy maintenance in the event of accidents are also important requirements for these rolls.

To meet these special needs, high-precision tube rollers with optional quick replacement heads have been developed.

Dynamic Balance In Accordance With ISO1940 Standards

Quality Grades G1.0, G1.6 and G2.5

Paper machine guide rolls are divided into two types: felt rolls and screen guide rolls. The application parts include pressing, drying, crimping, rewinding and other parts. Guide rolls guide and drive the wire and felt in the wet end and drying section of the paper machine. The guide rollers in both areas use the same bearings. However, different lubrication and sealing are used depending on the application location. Due to different working conditions, the wet end and dry section need to be lubricated with their own oil circulation.

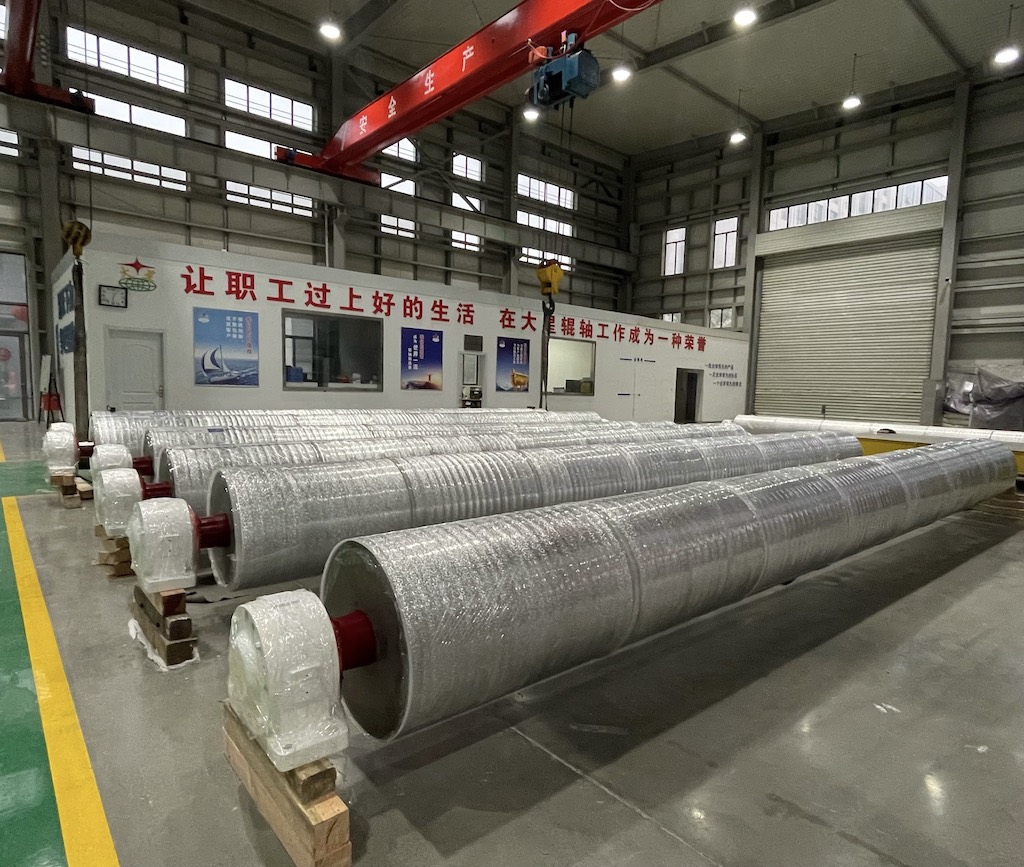

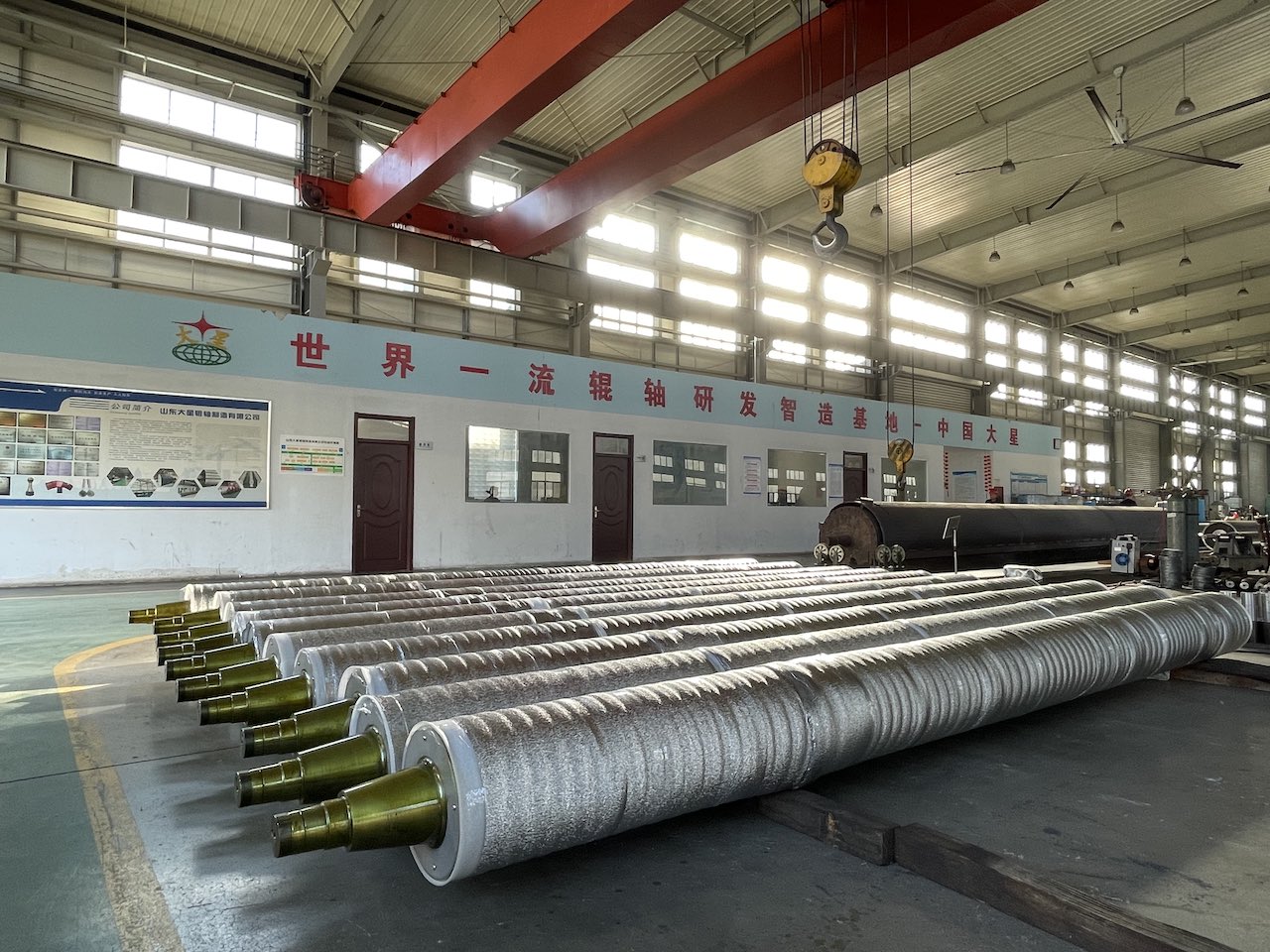

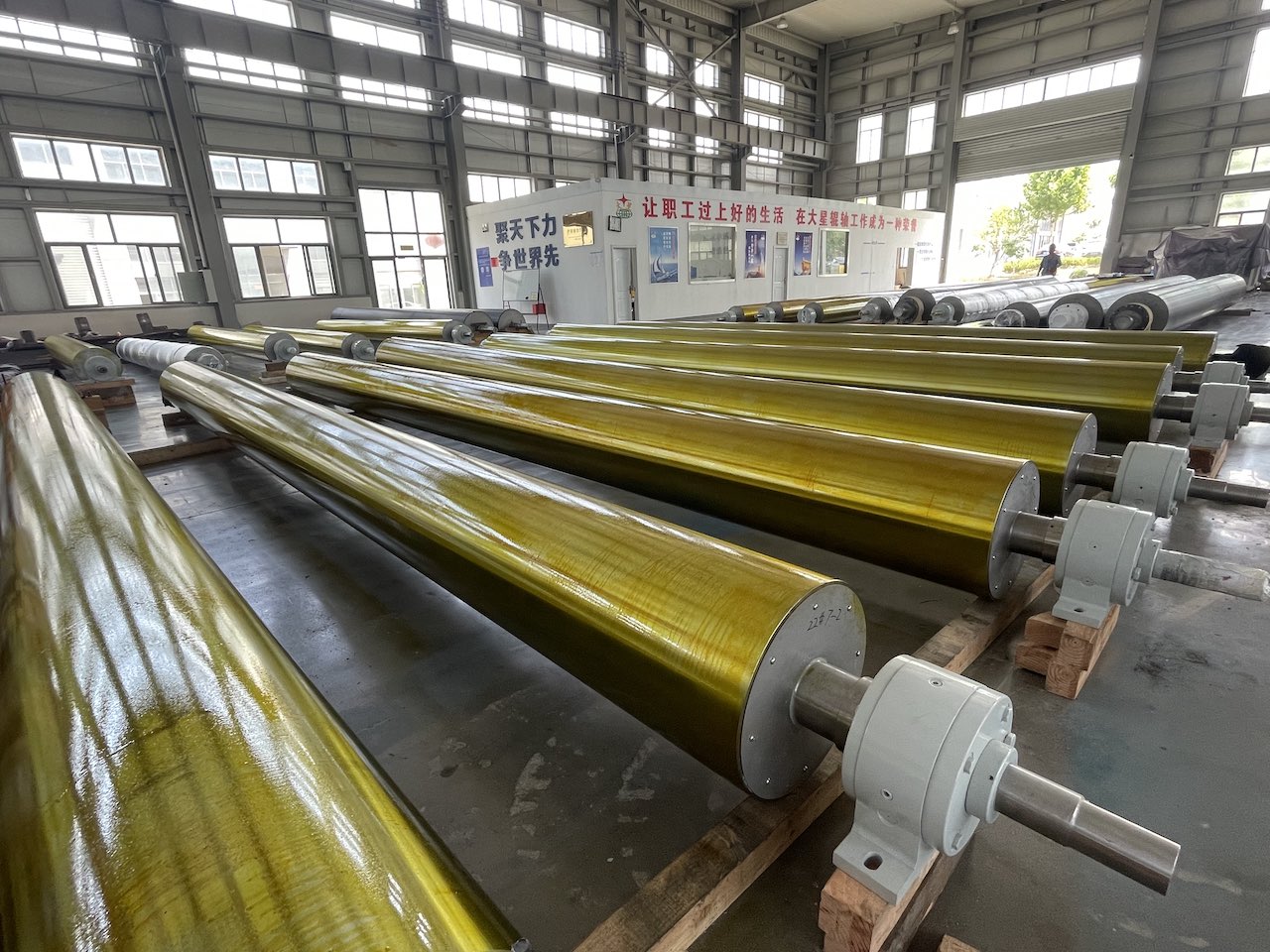

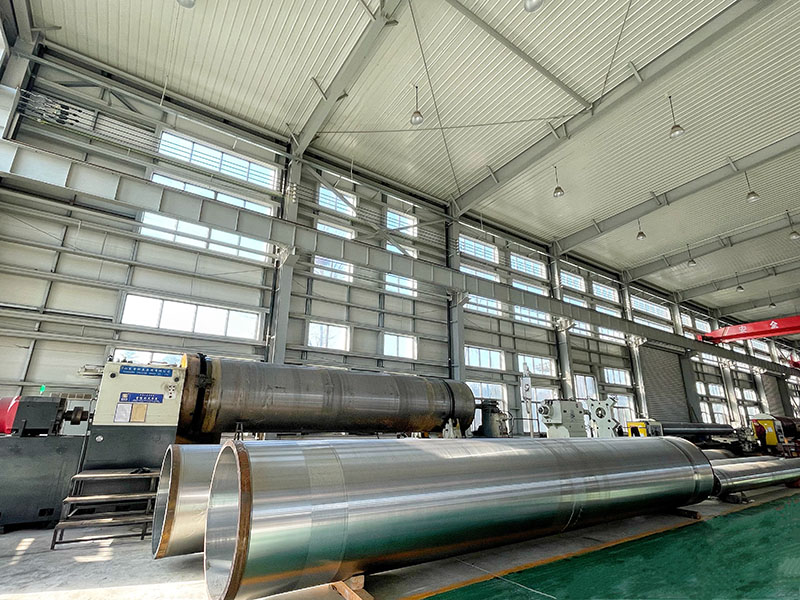

Company Pictures:

Exhibition Pictures: