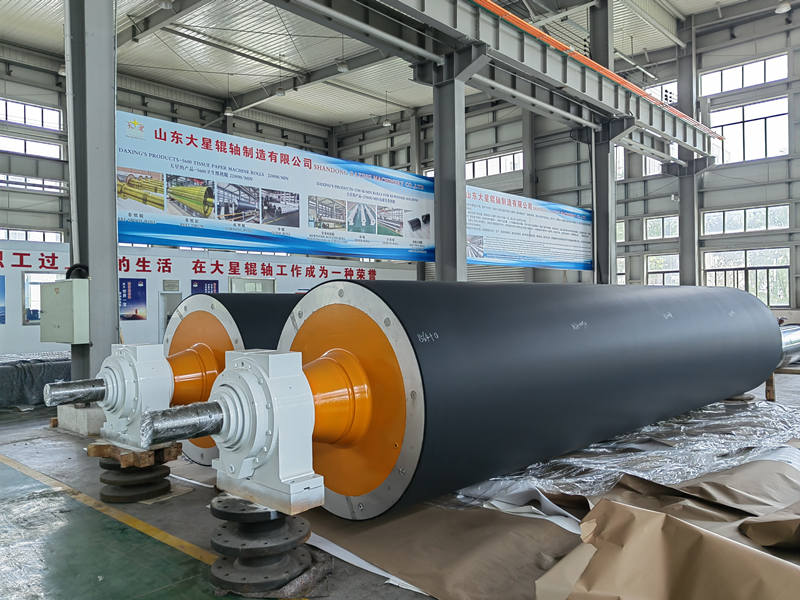

Press Roller Of Paper Machine Press Section

Daxing's High Performance press roller

Make Breast Rolls(Ceramic Rolls) for paper machine since 1978.

High precision machining lethes and balancing machines.

Following ISO 9001 Quality Management system.

Following ISO 45001 Health and Safety Management system.

Following ISO 14001 Environmental Management system.

Press roller used in press section for paper machine,The press roller shell material is cast iron HT 250-HT300 or forged steel .surface is covered with rubber or polyurethane (PU ) the thickness of rubber is 20-25mm.,shaft head: 35# cast steel , bulkhead: HT250.

Roller inside and outside surface will be processed.We will do dynamic balance to improve the stability of the roller.

Dynamic Balance In Accordance With ISO1940 Standards ,Quality Grades G1.0, G1.6 and G2.5.

Our processing capacity

Daxing has more than 70 sets of large-scale processing and testing equipment, 11 sets of processing equipment that can process roller surface 12 meters, and the maximum processing length can reach 16 meters. Excellent equipment ensures excellent product quality, and advanced testing equipment and management concept ensure that each set of roller shaft can meet international standards.

Packaging

Products will be packaged according to their shapes, weight, transport distance and transport modes. Large machines will be packaged in sections. Every part of export machinery will be in standard export wooden package, waterproof film, straw rope, carton box ,etc, which will ensure the intactness of the products.

Delivery

(1) sea transportation is from qingdao seaport or other ports.

(2) the delivery time is decided by your needed machines or machine parts. But it also follows your needs.