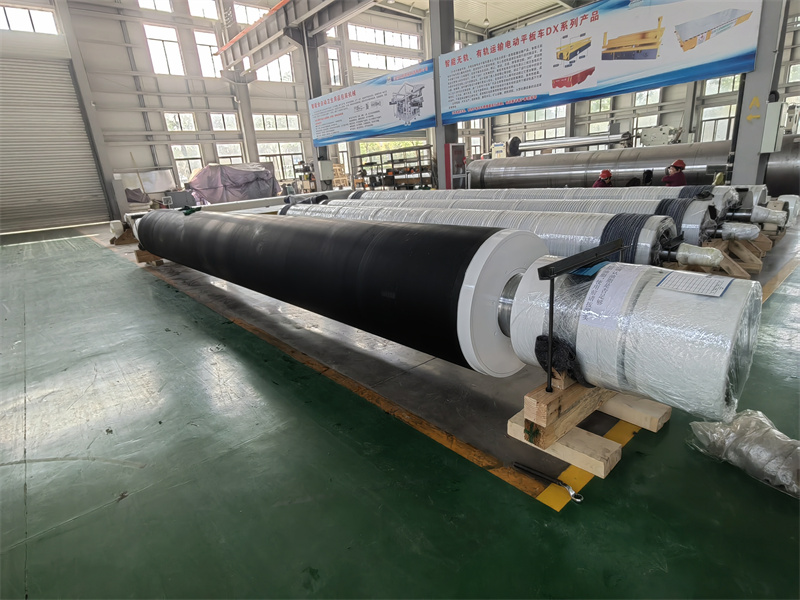

Spool Roll Of High Speed Winder Machine

Daxing's High Performance Reel Spool Rolls:

Make reel spool rolls for paper machine since 1978.

High precision machining lethes and balancing machines.

Following ISO 9001 Quality Management system.

Following ISO 45001 Health and Safety Management system.

Following ISO 14001 Environmental Management system.

3000m/min Balancing Speed with dynamic deflection curve.

spool roll for high speed winder

Diameter Range: | φ200-800mm |

Maximum Face Length: | 14000mm |

Shell Material: | seamless steel pipe or rolled and welded steel plate (Q235B,Q345D) |

Coating: | PU or Rubber |

Journal Material: | Forged 42CrMo; 42CrMo or Nodular Casting Iron |

Bearing housing: | Gray Casting Iron or ZG 35 or Nodular Casting Iron |

Bearing brand: | Chinese brand or SKF or FAG or NSK or Timken |

Connection type: | Flanged Joint |

A tube rolls with good performance is crucial for the operation of a paper machine.

High reliability and easy maintenance in the event of accidents are also important requirements for these rolls.

To meet these special needs, high-precision tube rollers with optional quick replacement heads have been developed.

Dynamic Balance In Accordance With ISO1940 Standards

Quality Grades G1.0, G1.6 and G2.5

Our production capacity :

Daxing has more than 70 sets of large-scale processing and testing equipment, 11 sets of processing equipment that can process roller surface 12 meters, and the maximum processing length can reach 16 meters. Excellent equipment ensures excellent product quality, and advanced testing equipment and management concept ensure that each set of roller shaft can meet international standards.