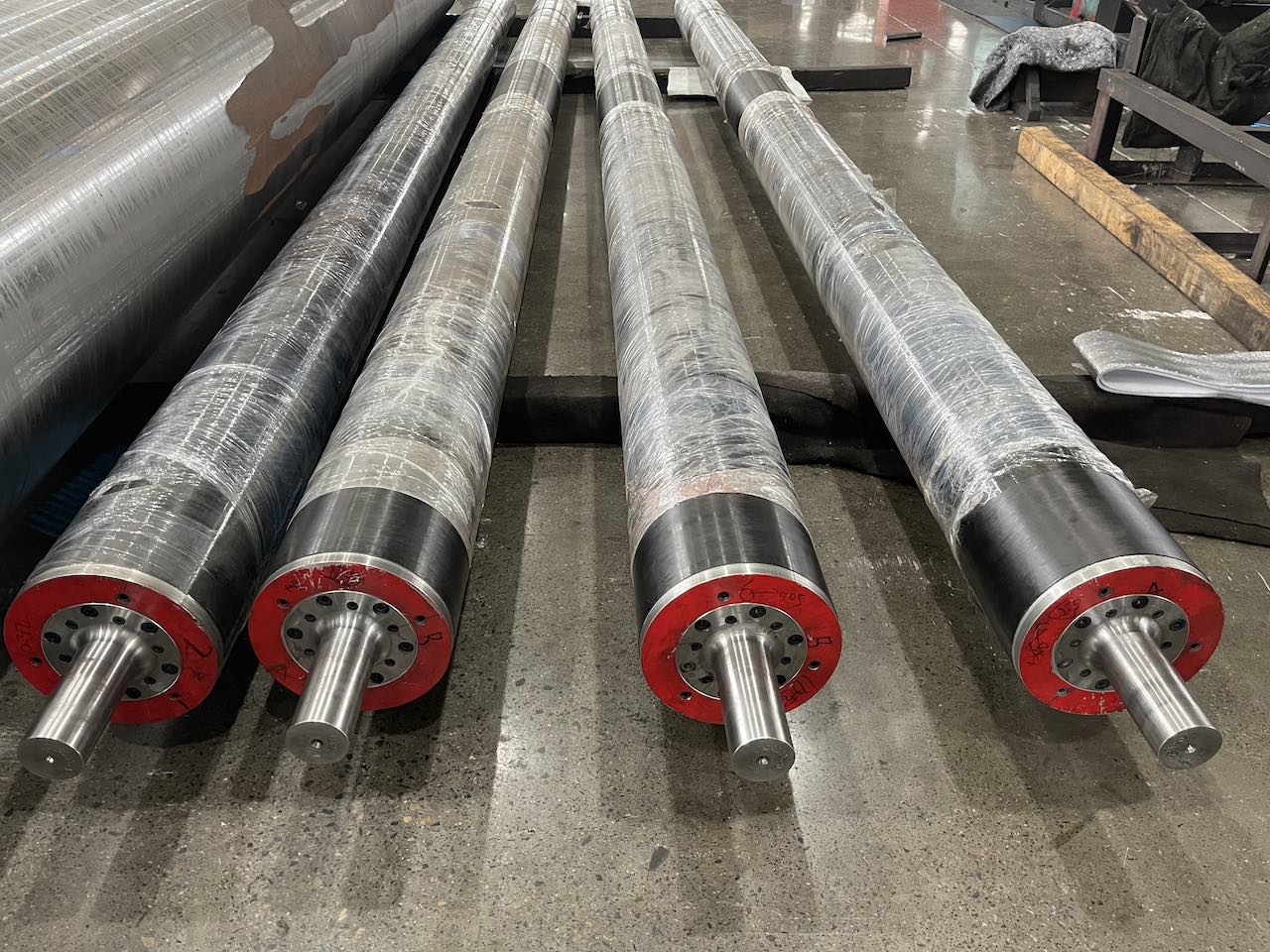

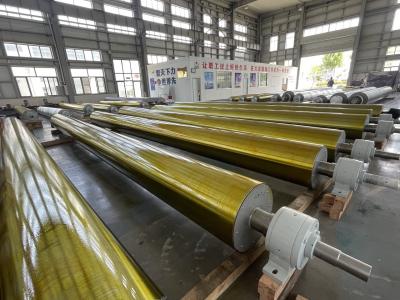

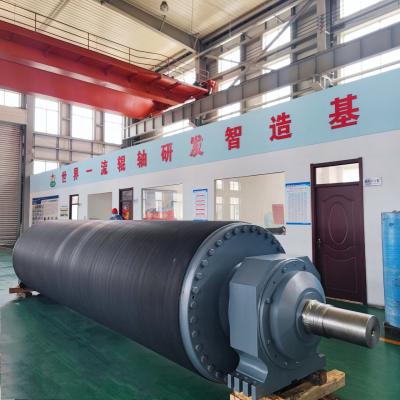

Carbon Fiber Roll of Film Production Line

1.Lighter weight: Improved safety

Roll replacement workability greatly improves, contributing to improved safety.

2.Lower inertia: Reduced running costs

Stable transport is achieved with thin material and low tensile force, and reduced drive energy helps reduce cost.

3.Low deflection: Improved product quality

Stable base material transport improves product quality.

4.High rpm: Improved productivity

While high rotational control is maintained, the critical speed is increased.

Carbon fiber roll has about ten times strength of iron, while its specific weight is about one-fourth that of iron.

Carbon Fiber Roll of Film Production Line

Design according to customer's using;

Reliable design and manufacture;

Product Information:

Carbon Fiber Roll | Manufacturing Standard Shell in carbon fiber Bulkhead in HT250 or Aluminium Journal in 42Crmo or Forged 42Crmo |

Optional Grease or thin oil lubrication Rubber cover or Chromed plating or RCC | |

Supply limits Max Diameter: 1000mm Max Face length: 14000mm Max Balancing speed: 2500m/min With Center dynamic deflection testing |