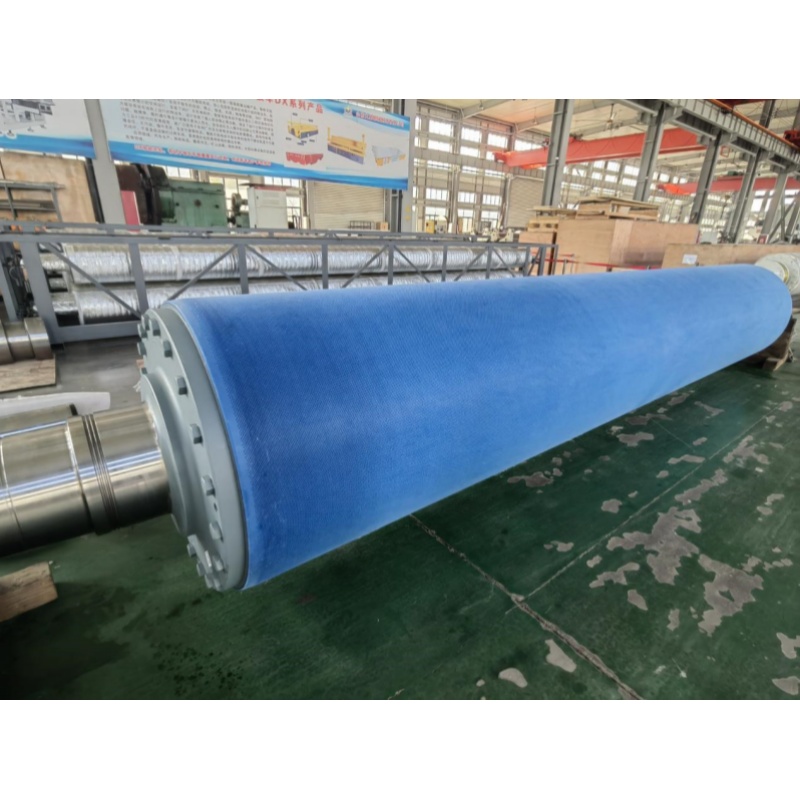

Blind Holes Press Roll For Press Section

Advantages of Blind Hole Press Rollers for the Press Section:

Improved Drying Efficiency: The blind hole design enhances moisture drainage, accelerating drying and reducing production time, increasing overall efficiency.

Reduced Paper Damage: By optimizing moisture removal, blind hole press rollers minimize paper tearing and deformation during the pressing process, ensuring high-quality output.

Strong Adaptability & Easy Maintenance: These rollers perform exceptionally well under high humidity and in various paper types. Their simple structure also makes maintenance and replacement easy, reducing downtime.

Blind hole press roller is a specially designed press roller widely used in the press section of paper machines. Its unique blind hole structure gives it significant advantages in the paper production process. The following is a detailed introduction to blind hole press rollers, including their structure, function, advantages, and applications.

1. Structure

-Material: Blind hole press rollers are usually made of high-strength steel or alloy materials, and their surfaces are specially treated to improve wear resistance and corrosion resistance.

-Blind hole design: The surface of the roller is designed with multiple blind holes, which do not penetrate but only form depressions on the surface of the roller. This design enables effective drainage of moisture during the pressing process.

-Surface treatment: The surface of blind hole press rollers is usually polished to reduce friction with the paper and lower the risk of paper damage.

2. Function

-Moisture removal: The design of blind holes allows for more effective drainage of moisture from the pulp when pressure is applied, thereby improving the drying efficiency of the paper.

-Paper forming: During the paper forming process, blind hole press rollers can help evenly distribute the pulp, ensuring uniform thickness and density of the paper.

-Reduce paper damage: Due to the presence of blind holes, rollers can better control the removal of moisture during the pressing process, reducing paper damage during the pressing process.

3. Advantages

-Improving drying efficiency: Blind hole design can effectively increase the drying speed of paper and reduce production time.

-Reduce paper damage: By optimizing the moisture removal process, the tearing and deformation of paper during the pressing process have been reduced.

-Strong adaptability: Suitable for various types of paper production, especially performs well under high humidity conditions.

-Easy maintenance: The structure of blind hole press rollers is relatively simple, and maintenance and replacement are convenient.

4. Application

-Production of cultural paper and packaging paper: Widely used in the production of cultural paper, packaging paper, and other types of paper, it can meet the high requirements for paper quality.

-High speed paper machine: In high-speed production lines, blind hole press rollers can effectively improve production efficiency and ensure stable paper quality.

Blind hole press rollers play an important role in modern paper machines due to their unique design and superior performance. They not only improve the drying efficiency and quality of paper, but also reduce the risk of damage during the production process, making them an ideal choice for many paper companies.