Groove Jumbo Press Roll

Jumbo Press roll normally refers to a nip composed of pressing rollers which a diameter from 1000mm to 1600mm. It is often used in the production of corrugated paper, cardboard, and other paper or cardboard with large basis weight.

Comparing with original presses type, it has a wide nip formed by the large-spoke press, the paper sheet can be pressed for a long time in the nip. It can improve the dehydration efficiency, increases the de-watering capacity and paper quantity because of the two-way vertical dehydration design.At the same time, it can also reduce steam consumption in the dryer section and further reduces production costs. The strength and burst resistance of the paper also been improved.

Due to the large linear pressure between the rollers and the high load, a large heat will appear between the two rollers during the paper machine running. In order to protect the surface coat rubber, we added a water inlet at the end of the operation side shaft head, the circulating water is passed through the spoke body for cooling.

Usually, the paper machine adopts this technology has the feature of high speed, low energy consumption, and good paper quality. Therefore, jumbo pressing technology and equipment have become the first choice in the speed-up and energy-saving of old paper machines and the design of new paper machines.

Jumbo Press Roll Specification:

Diameter Range: | φ1000-1600mm |

Maximum Face Length: | 14000mm |

Shell Material: | Gray Cast Iron; Steel |

Surface type: | Blind Hole, Blind + Through Hole; Smooth or Groove |

Coating: | PU or Rubber |

Journal Material: | Forged 42CrMo; Cast Steel or Nodular Casting Iron |

Bearing housing: | Gray Casting Iron or ZG 35 or Nodular Casting Iron |

Bearing brand: | Chinese brand or SKF or FAG or NSK or Timken |

Connection type: | Flanged Joint |

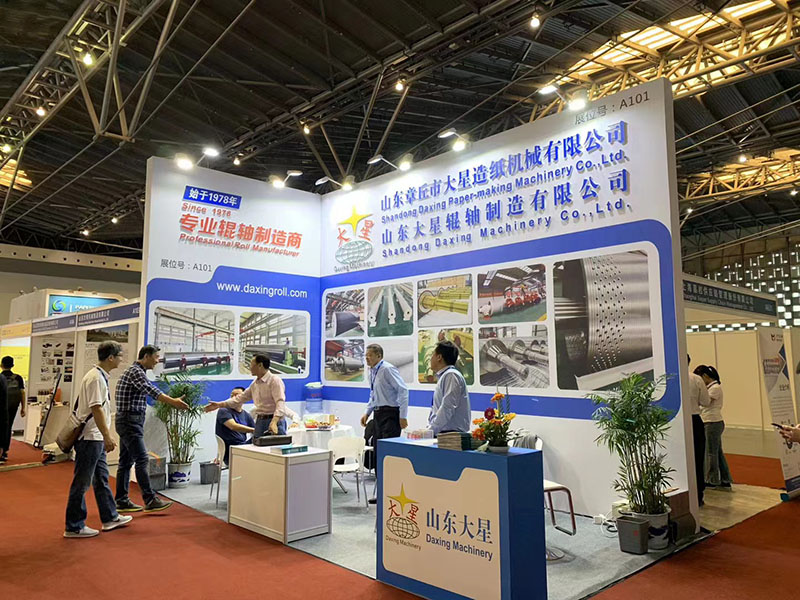

Company Pictures: